That’s the current state of the armoire. All the drawers completed. Well, except for the cleanup portion of that program. I’ll have to trim all the corners flush as well as scrape the fronts. But for now, I’ve moved on to other elements of construction. The top to be specific. Not the top-top, the bottom-top. You know, the part that goes over the top drawer?

I’ve made some decent progress. Here’s a preview of the bottom-top:

I’ve done this three-sided border technique before and I like it for a couple of reasons. First, it hides the endgrain of the boards. I know it’s typical to just deal with it, but since it’s my project, I choose not to. I didn’t want to make the top a floating panel style, so instead I’ve opted for this technique. The long edges will be splined together so the surface will be flat and unbroken. The edges will also be splined into the border for stability, but I won’t glue that edge. Thus, the boards can expand and contract as needed without causing problems.

For extra strength, I double biscuit the mitre joints of the border:

The rabbet around the inside-bottom edge of the border sits down on the top of the posts, so the top is registerd with the carcass. I didn’t intend for the spline groove to run into the biscuit slot. Hey, stuff happens. I don’t think it’ll affect the integrity of the piece.

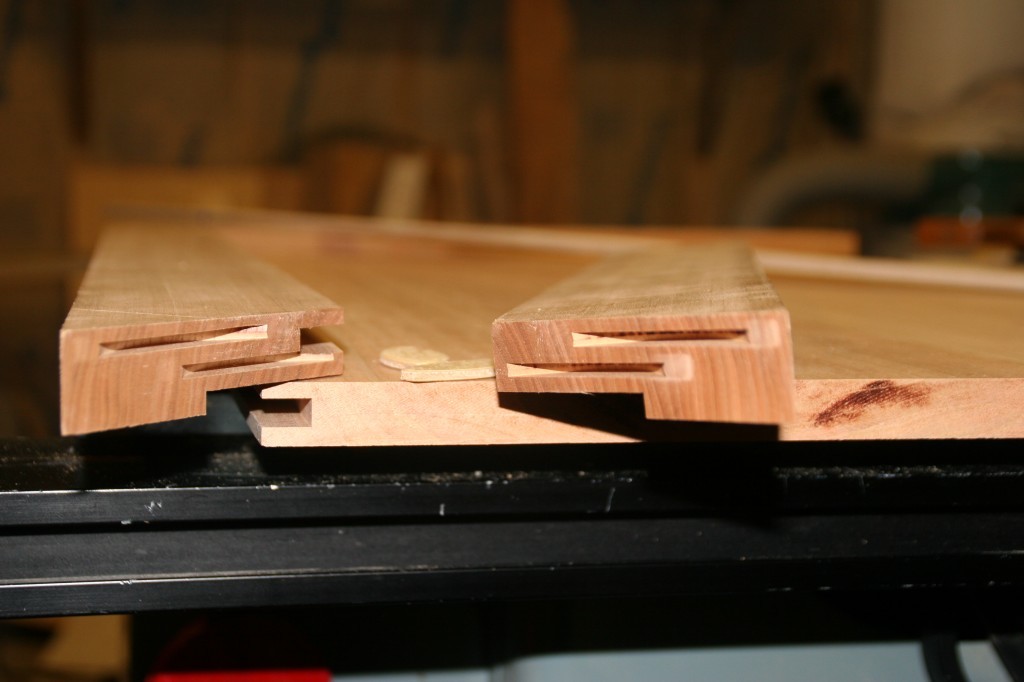

Here’s a shot of the splining which I made using 5/16×1″ maple stock:

To make all the joinery as perfect as possible, I fashioned myself a couple of shooting boards. One is a simple bench-hook style board. It’s about 12″ wide with a 2″x1/4 piece glued and nailed for the cleat on the top (that’s what I’ll set my board against) and a 1″ square cleat on the bottom end (to hook onto the edge of my workbench). The board itself is about 5 feet long. Here’s the other shooting board:

The cleat on the top is permanent so I can shoot perfect right angles on the ends of my boards. I also fashioned the add-on mitre cleat so I could shoot mitres. I got to put that part through it’s paces today and it worked out fantastic. After cutting the mitres with a saw, I tuned them to perfection using the mitre cleat on the shooting board. I never realized how much better I could fit the mitres together until today. I was able to fit the mitred edges together with no gaps in the seam and the two pieces flush against one another.

The only caveat to using these jigs is the plane. The one in the picture is a Lie Nielsen 14″ low-angle jack plane. Because of it’s length, it’s probably not the best choice of plane to use- but it’s the only one I had that I could work with so I made due. I had a lot of trouble, initially, pushing it across the wood. I ended up sharpening it and that made a HUGE difference. Clearly, for best results with shooting boards, the plane blade has to be sharp enough to split hairs and the plane bed needs to be flat. Ideally, the side of the plane should be flat and smooth to reduce friction while pushing the plane. Luckily, with Lie Nielsen, the flat bed and sides are a feature. The blade, however, needs to be sharp. I got mine sharp enough to remove slice of endgrain that were thinner than paper.

As for completing the top, my plan is simple. I’ll clamp the border together and set it upside down on the workbench on top of the boards that will form the field. I’ll then mark those boards and cut them to size. Then I’ll shoot the boards to get the fit where I want it. Finally, I’ll use my router to create grooves in the sides of the border and the ends of the boards which I’ll then insert a spline into. Then it’s just a matter of gluing it all together. Only the mitres and long edges of the boards will get glue. I’ll probably glue down the edge an inch or 2 at most.

2 replies on “Armoire Blogging”

You might want to wax the edge of your plane with beeswax. It will make it run smoother on the shooting board.

The job looks great so far. I look forward to seeing the final product.

I’ve seen the trick about the wax. I intend to add that as well. I think I’ll also make a shooting board for jointing as well.

You should make a couple. It’s amazing how much precision they afford when fitting joints.